Last week, both the Senate and the House of Representatives passed the CHIPS

HIPS

But passing the bill isn’t just a win for the Biden administration, it’s a win for the supply chain, too.

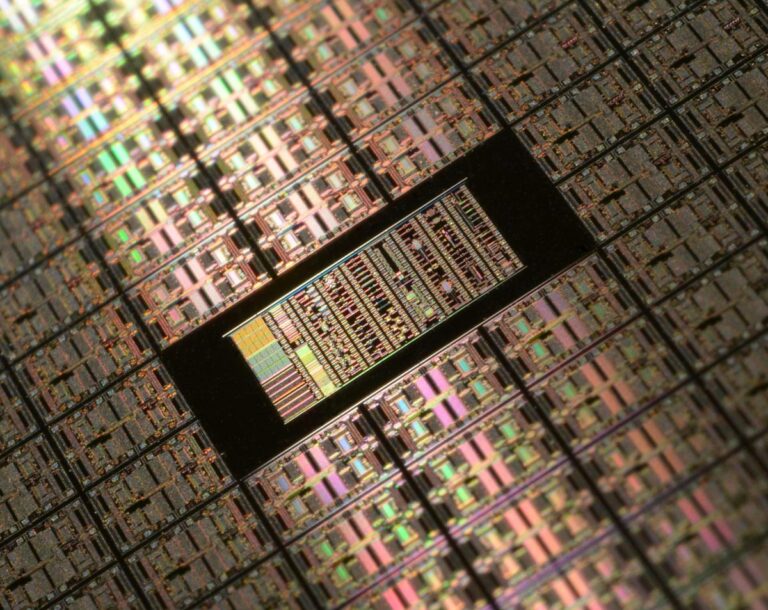

We’ll be seeing a lot more of these made in the US in the coming years.

The CHIPS Act Bolsters America’s Future

Of the $280 billion in CHIPS Act subsidies, more than $50 billion will go to semiconductor manufacturing and research. Nearly $200 billion will go to R&D of other technologies including AI, robotics, quantum computing, and biomedical research. $10 billion will be used to create regional technology hubs around the country aimed at driving innovation, with another chunk aimed at workforce development programs to help fill the jobs created by these programs.

It’s a ton of money and foregone tax revenue meant to bolster national security by reducing our reliance on imported semiconductors and strengthen the economy by reshoring tech manufacturing and fostering innovation here in the U.S.

The legislation is a direct response to the semiconductor supply chain issues magnified by the pandemic — the goal is to ensure that American companies have access to the advanced chips necessary to innovate in key fields like artificial intelligence, biotechnology, and 5G. And while the chip shortage is easing in some sectors, plenty of companies are still struggling to get the silicon they need.

Reshoring Benefits Everyone

This massive investment by the U.S. government strikes me as a sound one because increasing the stateside manufacturing base creates more supply chain options for everyone, non-US countries included. More options make for a more robust and resilient supply chain through increased geographic diversity, simplified logistics, and reduced risk.

Digital Manufacturing Can Help Realize the CHIPS Act’s Potential

And while semiconductor and cutting-edge technology companies and startups stand to benefit greatly from the bill’s passage into law, I believe that digital manufacturing has a critical role to play in helping the CHIPS Act realize its full potential and maximize its positive impact.

The new chip fabrication plants built with the influx of CHIPS funding will leverage robotics and other automation technologies, which need custom Maintenance and Repair Operations (MRO) to keep production lines working. Digital manufacturers excel at crafting the precision components required by automated production lines, and they simplify and accelerate the process of procuring mechanical parts with efficient, plug-and-play digital workflows. Plus, the speed at which digital manufacturers operate enables a cost-effective digital inventory approach.

Additionally, the investments in R&D will drive the creation of new, innovative products. But developing those products requires custom manufacturing support to help engineers and designers refine their ideas and get them to market — and digital manufacturers are ideally suited to deliver the low-volume, high-mix, complex parts that folks in cutting-edge fields need to bring their ideas to life.

I’ve no doubt that the CHIPS Act will be a boon to American innovation for years to come, and I’m excited to see what new products and technologies are created because of it. But I’m even more enthusiastic about the opportunity to play an active part in the innovation boom… how about you?