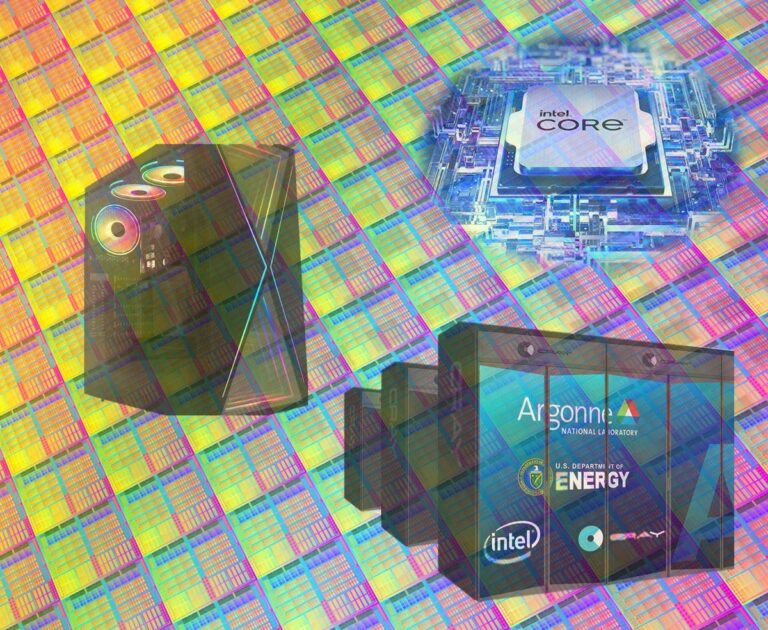

Moore’s Law has powered everything from semiconductors through the largest supercomputers.

Over the past 50 years, the electronics industry has transformed society. People and machines have become more productive, information is now available in milliseconds, the majority of the population is now connected to the rest of the world 24/7, advanced healthcare has extended life expectancies, and machines have become smarter, and in some cases even autonomous. Advancements in semiconductors sit at the heart of these achievements. Semiconductors are the digital DNA building blocks of society. They are so important that governments around the world are promoting, investing, and protecting semiconductor intellectual property and manufacturing, most recently through actions such as the European Chips Act and the U.S. CHIPS and Science Act.

Today’s semiconductors grew out of a need to shrink electronic components to fit advanced electronic systems cost effectively into increasingly compact form factors. This dynamic is the driving force in technology advancement and is linked to a principal we know as Moore’s Law. Various interpretations of Moore’s Law have led to many conclusions in the market. Some say that Moore’s Law is dead; others say it is very much alive; and others, including as myself, say that Moore’s Law is evolving and remains the heartbeat of innovation.

Separating Truth From Myth

Intel Co-founder Gordon Moore

Because of the many misconceptions regarding Moore’s Law, the best place to begin is to understand what Gordon Moore really said. Gordon Moore, a founder of and Director of Development at Fairchild Semiconductor and a future Intel co-founder, published an article in 1965 that appeared in Electronics magazine, the leading electronics industry publication of the day. The article’s title was “Cramming More Components onto Integrated Circuits.” While most of Moore’s article focused on predictions of what will be possible with future electronic systems, the article’s central thesis was based on only five data points starting with Fairchild’s original silicon transistor. That observation was that the rate of integration per square millimeter will continue to increase exponentially on an annual basis. His exact words were:

Moore’s Law graph from 1965

“The complexity for minimum component costs has increased at a rate of roughly a factor of two per year (see graph on next page). Certainly over the short term this rate can be expected to continue, if not to increase. Over the longer term, the rate of increase is a bit more uncertain, although there is no reason to believe it will not remain nearly constant for at least 10 years. That means by 1975, the number of components per integrated circuit for minimum cost will be 65,000.

I believe that such a large circuit can be built on a single wafer.”

The full article is available in the Computer History Museum Archives, as well as on the Intel website.

In this article, Gordon Moore accurately predicted the next 10 years of progress for integrated circuits (ICs) and the electronics industry based on his observation. It is important to remember that this observation and the other predictions made by Dr. Moore were based on the technology available at the time, which was 2D, referred to as planar, integrated circuit designs. Approximately a decade later, Dr. Moore revised the doubling period to two years. Even back then, Moore’s Law was not carved in stone.

Scientific Laws generally refer to natural phenomena. Note that these observations and conclusions are called “theories” until they can be verified through some scientific method. In a 2015 interview, Moore himself said, “”…I just did a wild extrapolation saying it’s going to continue to double every year for the next 10 years.” So, calling Moore’s observation a “law” is a bit of stretch, and Moore didn’t make that stretch himself. Another electronics pioneer, a Caltech professor named Carver Mead, popularized the term. However, Moore’s observation was a very accurate prediction of one of the key innovations that have driven the advancement of electronics technology over the last half century.

The Pillars Of Innovation

The Pillars of semiconductor innovation – Manufacturing Technology, Materials Science, IC Design, … [+]

Maintaining the pace of Moore’s Law has required constant innovation in several areas, or what I like to call the semiconductor pillars of innovation. These innovation pillars include manufacturing technology, materials science, design, and more recently packaging technology. The first three pillars have evolved simultaneously and work together to achieve higher density and performance efficiency while overcoming increasing complexities and higher implementation costs.

Progression of semiconductor processes technology

The manufacturing pillar includes the ability to produce circuits that are smaller with each generation of process technology, requiring progressive advancements in lithography technologies to shrink the design geometries of the circuit elements, particularly the transistors. The semiconductor lithography process uses photomasks to transfer a design to a silicon substrate using lenses and a high-power light source. Once improvements in the light source stalled at 193nm, the industry began using multiple mask layers and water immersion to amplify and improve image resolution for creating smaller design elements. More recently, the industry has begun using Extreme Ultraviolet (EUV) lithography technology, which uses a much finer 13.5nm wavelength light source (soft X-rays) with mirrors instead of lens in machines that cost upwards of $150 million each, are the size of a small house, and require four jumbo jets to ship. Today’s semiconductors typically combine the various technologies in an efficient manner.

The ASML nxe3400 EUV lithography system

My second pillar is materials technology. Although the silicon wafer remains the primary substrate for manufacturing semiconductors, the materials used in the manufacturing process continue to evolve. Think of the materials as a control lever where changing the chemical composition impacts the power and/or performance characteristics of the chip, as well as the ability to manufacture at high yield rates. The semiconductor industry continues to test various chemical combinations with new processes and circuit designs to achieve design performance and power characteristics with the highest possible yields.

My third pillar is circuit design, more specifically the design of all circuit design elements. The most fundamental circuit element is the transistor, which is used to control and/or modify electrical signals. An IC combines transistors and other design elements into one chip design. Shrinking these on-chip elements is the foundation of Moore’s Law because the design of the transistor and other elements play a key role in achieving higher circuit performance, efficiency, and density.

From the beginning of semiconductor manufacturing through the 28nm process generation, the industry used traditional 2D “planar” transistor designs. However, shrinking these designs below 28nm led to an unfortunately side effect: higher leakage current. This led to the innovation of the 3D transistor. The 3D transistor stands upright with the gate surrounded by the channel to carry current on three sides, giving chip designers more area on the transistor to better improve circuit performance and leakage. The industry named this new type of transistor a “FinFET” because of its fin-like appearance. Intel was the first company in the industry to have a commercial FinFET process and began using FinFETs at the 22nm process node. The rest of the industry transitioned to FinFETs later, at the 16/14nm process node.

Modern FinFET and RibbonFET transistors used in IC design

The industry is now beginning to transition to a gate-all-around (GAA), also referred to as RibbonFET, transistor design that will wrap the transistor’s gate with material on all four sides. This architecture also allows for the stacking of transistors that will further improve performance, efficiency, and density of ICs.

Advanced 2.5D and 3D semiconductor packaging

My fourth pillar is packaging technology. While ICs have always been encapsulated using various package types, packaging was primarily used to separate different functions into discrete parts for economical manufacturing and to be incorporated or “socketed” into larger systems on printed circuit boards (PCBs). Each part is often manufactured using a semiconductor process generation that is best suited for the function in terms of performance, heat, power, and cost. However, as circuit and system performance requirements have begun to exceed the speed, size, and power limitations of PCBs, it has become necessary to move individual circuits into the same IC package through the use of silicon substrates or by stacking silicon dies, referred to as 2.5D and 3D circuits respectively.

Note that semiconductor cooling technologies are closely tied to packaging and systems technology. The development of advanced cooling techniques has allowed for higher performance integrate circuits.

The Essence Of Moore’s Law Remains Unchanged

Even though the use of new process technologies, 3D transistors, and alternative packaging were not envisioned by Dr. Moore in his paper, they have been critical technologies in furthering the trend identified in Dr. Moore’s 1965 article for increasing transistor count and density. In its most basic interpretation, Moore’s Law is a measure of density achieved at an economical cost and within operational limits. While it has traditionally been measured by the number of transistors per square millimeter (mm2), there is nothing inherent in Moore’s original observation that says density must be measured in that manner. In essence, the measurement, if there is one, would now be transistors per cubic millimeter (mm3), but even that figure of merit has its limits.

The true nature of Moore’s Law, or more accurately Moore’s observation, is that IC density will continue to increase. This increase in density will result in increased compute capabilities that will drive innovation throughout the electronics industry and help transform society. Even as the industry approaches the single-atom physical barrier of circuit design, there are efforts to develop alternatives to digital circuits implemented with transistors, such as quantum and neuromorphic computing, that will change the way ICs are designed and manufactured.

Some believe that Moore’s Law is dead. Tirias Research believes that this is inaccurate because Moore’s Law is not a scientific law. Moore’s Law is an observation and prediction that has lasted for more than half a century and continues to drive the semiconductor industry to continue pushing the pace of electronics innovation with each new generation. My next post will address this link between demand and the innovation enabled by Moore’s Law.